The Types of Rock Bolts

Grout-Anchored Rock Bolt

A grouted rock bolt is a threaded bar made of steel, or rebar bolts. Once drilling is done and this steel bolt is inserted, cement grout or resin grout can be used as the grouting agent. For reinforcement, a cable bolt made of steel wires intertwined as a steel rope is placed with the grout in the borehole. A bearing plate is used on the fully grouted rock bolt on the surrounding rock face to create tension and stabilize the rock.

Cable Bolts

Cable bolts can be used for temporary or permanent rock reinforcement. These bolts allow for tensioning without tensioners. They have a free length or threaded anchorage instead of a barrel and wedge system that is often found. This allows for a more flexible system, even when using longer cable bolt lengths. Cable bolts have a low bolt weight, but a high load-bearing capacity. Installation can be completed with cement cartridges, resin cartridges, cement grout, or injection resin. These are great for conditions with limited space and work well for the reinforcement of roadways and gateways.

Hollow Rock Bolts

These steel bolts have a hole in the center and were made to ensure a reliable grouting process. The hole is used for grout, eliminating entangling tubes. This type of bolt can have the same cone and wedge anchor mechanism. When using the bolt facing downward, the grout is applied in the hole and then a short tube is inserted to get rid of any trapped air. When using the bolt facing upward, a short tube is used for grouting and the central hole is left clear for a breathing tube.

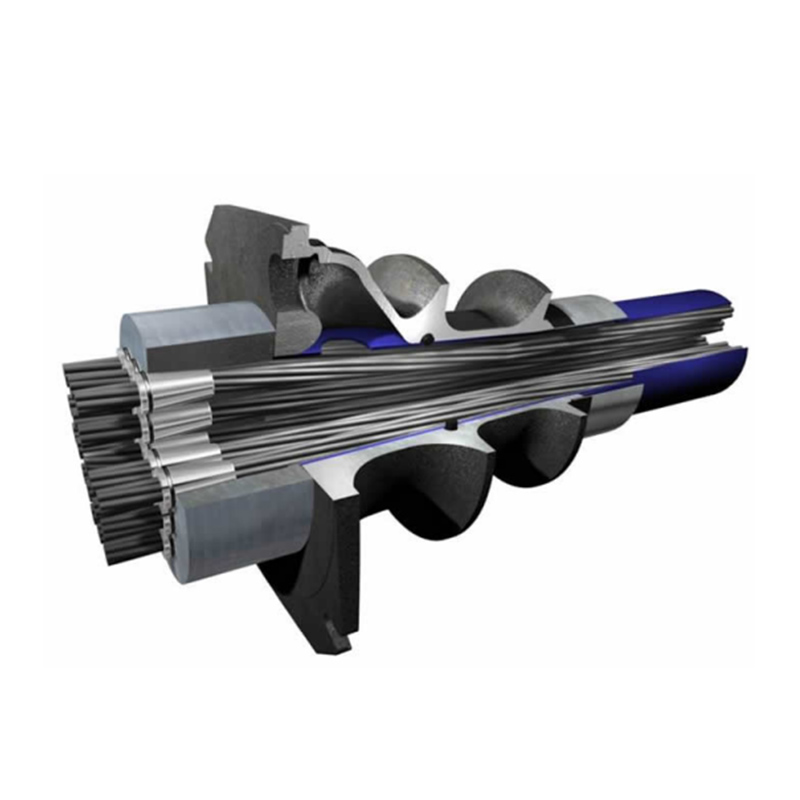

Self-Drilling Rock Bolt

These types of bolts are made out of a hollow bar that is fully coarse threaded. It can be used in roof and wall bolting, in the ground, for installation with grout, and can be placed temporarily or permanently. A self-drilling rock bolt acts as the drilling rod (it is not necessary to pre-drill a hole) as an anchor rod and a grouting pipe. A splicing system is available to create a longer tendon length. These bolts can be found with a T (trapezoidal) or R (rope) for tread profiles and have diameters from 25 to 76.

Mechanically Anchored Rock Bolts

This type of bolt uses an expansion shell instead of grout. This is much like how a drywall anchor works. As the bolt is rotated, the wedge that is attached to the bolt shank gets pulled into a conical shape. The shell is anchored with both friction and interlock. The mechanical anchor can be tensioned with a hanger or faceplate. This will distribute the load more evenly along the rock face to provide rock reinforcement.

Featured content:

Boost Your Home's Energy Efficiency with an Insulating Joint

Rapid Tooling: Revolutionizing Manufacturing with Speed and Efficiency

Plastic Injection Molding: Crafting Innovation and Precision

Unlocking the Magic of Vacuum Casting: A Revolutionary Manufacturing Process

Wrought Iron Ornamental: Adding Timeless Elegance to Your Home

Powder Coating Pickets: Enhancing Durability and Style

The Allure of Cast Iron Decoration: Unveiling Its Timeless Beauty

Friction-Anchored Rock Bolts

The friction-anchored rock bolt is one of the newest advancements in rock bolt techniques. A radial force is used against the borehole wall along the entire length of the bolt. This creates a frictional resistance to sliding after bolt installation.

MDX Bolt

If working in an area with seismic rock conditions, the MDX bolt will provide more ground support stability. Seismic events make it even more dangerous to be working under the ground and it is very important to use a rock bold that can handle the squeezing ground.

The MDX bolt can be installed simply in a single pass and has huge expansion and load-bearing capabilities. The design enables to bolt to handle significant loads with a small amount of displacement. These bolts have a spacial wedge that can expand up to 60mm. This provides a solid anchor in the wall without needing grout or resin.

Fiber-Reinforced Polymer Composite Rock Bolts

When working in places with harsh environmental conditions, such as in coal mines, steel bolts deteriorate quickly. They can sometimes fail within a matter of days. In these tough conditions, fiber-reinforced polymer (FRP) rock bolts can work better because of their corrosion resistance.

This makes them more suitable for conditions that have harsh chemical and alkaline environments. These bolts are non-conductive, light weight, easy to install, durable, are dimensionally stable under thermal loading, have an anti-static rating, and can also be cut without creating sparks.

Dowel

A dowel is simply an untensioned steel rod that is placed in the borehole after drilling in the rock mass and grouted in place. It is not threaded, does not have an anchor head, and needs ground displacement for activation. When joints become subject to displacement, the dowels will withstand both shear and tensile stresses. The ratio of the shear and tensile stresses will depend on the grout material and the make-up of nearby ground support.

The Importance of Porous Metal Filter Elements in Industrial Applications

Unleashing the Power of the Metal Asymmetric Filter Element: A Game-Changer in Filtration Technology

Metal Components: The Building Blocks of Modern Innovation

Benefits of Using a High Pressure Washer Nozzle

The Most Precise Metal Casting: Achieving Unparalleled Accuracy in Manufacturing

Types of Scaffolding Fittings: Enhancing Construction Stability

How Does a Pneumatic Piston Pump Work?

585

0

0

All Comments (0)

Previous: Easy Install Welded Mesh Gabion Basket

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments